Descripción del producto

Sensor de viscosidad en línea de libre mantenimiento para mediciones precisas y seguras en tiempo real directamente del proceso.

Datos técnicos

Propiedades

- Material

- 1.4571 / 1.4404 (316Ti / 316L)

- Clase de protección

- IP65

- Temperatura de proceso

- -10°C … +130°C | (integriertes Pt100 im Messfühler)

- Presión máx. de proceso

- Vakuum ... 64 bar

- Conexiones de proceso

- NPT | M48 | Varivent® | Tri-Clamp

- Longitud del cable sensor - transmisor

- Max. 1.000 Meter

- velocidad máx. de flujo

- 5 m / sec

- Aprobación Ex

- II 1/2G Ex ia IIC T6...T3 Ga/Gb | (optional)

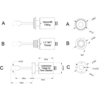

Tipos de sensores

- Esfera

- VA-100B

- Cilindro

- VA-100C

Repetibilidad

- VA-100B

- ± 0,5% | ± 1 Digit

- VA-100C

- ± 0,3% | ±1 Digit

Rangos de medición

- VA-100C

- 0,1 - 2.500 mPa·s x g/cm³

- VA-100B

- 10 - 25.000 mPa·s x g/cm³

Dimensiones de la sonda

- VA-100C

- Ø 32 x 145 mm

- VA-100B

- Ø 32 x 120 mm

Posiciones de instalación

- Depósito

- Tanques

- Tubería

- celda de flujo

- La instalación es independiente de la posición

ViscoScope® VA-100 Configurar

VA-100 - [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ] - [ 5 ]

product description

Más información del producto

Viscosímetro de proceso en línea

- Medición reproducible de la viscosidad en tiempo real

- Optimización de la producción / Control de calidad

- Instrumento de medición libre de mantenimiento

- Instalación sin espacios muertos (apto para CIP / SIP)

- Económico

- Ámbitos de aplicación: industria química, petroquímica, alimentaria, farmacéutica y cosmética

El sensor ViscoScope® VA-100 es un viscosímetro de proceso sin mantenimiento diseñado para la medición precisa, reproducible y confiable en tiempo real de la viscosidad dinámica de líquidos. Un Pt100 integrado en el cabezal de medición mide simultáneamente la temperatura del proceso. El sistema ViscoScope® se calibra en fábrica con aceites newtonianos certificados. El sensor está disponible en dos versiones de sonda, con conexión por rosca NPT, brida especial o acoplamientos higiénicos. Las celdas de flujo estandarizadas o diseñadas a medida permiten instalaciones incluso en tuberías de pequeño diámetro.

Todas las partes en contacto con el proceso están completamente soldadas. No hay piezas móviles que puedan desgastarse ni generar fugas que dañen el interior del sensor. En cada viscosímetro ViscoScope® se encuentra un Pt100 integrado en la sonda de medición. El sensor VA-100 se fabrica en serie y está disponible en una clase de temperatura con tres variantes de conexión al proceso.

La sonda de medición del sensor ViscoScope® está completamente soldada, por lo que ninguna parte móvil entra en contacto con el líquido a medir. Bobinas eléctricas excitan la sonda a su frecuencia de resonancia, provocando una torsión oscilante de baja amplitud. Un regulador PID rápido en el transmisor mantiene constante la amplitud. Es decir, cuanto mayor es la viscosidad, mayor es la tensión necesaria, lo que constituye una medida de la viscosidad dinámica en mPa·s x g/cm³ (η x ρ).

La baja amplitud a la frecuencia de resonancia evita la fatiga del material, asegurando que no se desajusten ni desgasten componentes.

---------------------------------DAS HIER UNTEN IST ENGLISCH-SPANISCH-------------------------------------------------------

Los sensores ViscoScope® están fabricados con acero inoxidable de alta calidad y primera clase, y destacan por su diseño inteligente y robusto. Todos los componentes en contacto con el proceso están completamente soldados. Al no existir piezas móviles, no se produce desgaste ni se generan fugas que puedan dañar el interior del alojamiento del sensor. Cada viscosímetro ViscoScope® incorpora una sonda de temperatura Pt100 integrada en el sensor. El sensor VA-100 para la medición de viscosidad, se fabrica como estándar y está disponible en dos variantes de sonda dentro de una misma clase de temperatura y con tres tipos distintos de conexiones al proceso.

¿Busca un viscosímetro en línea fiable y sin necesidad de mantenimiento para optimizar su proceso de producción? Tenemos la solución ideal. Con el viscosímetro de proceso ViscoScope® es posible medir en tiempo real los parámetros de viscosidad y temperatura.

Este viscosímetro en línea es apto tanto para procesos continuos como por lotes.

- En procesos continuos, la viscosidad se monitoriza de forma permanente. Esto permite, por ejemplo, una dosificación óptima de disolventes en sistemas de recubrimiento abiertos, el control de la temperatura del medio con el fin de mantener una viscosidad constante (como en aplicaciones de adhesivos) o la determinación de la distribución de masa molar.

- Las aplicaciones por lotes suelen corresponder a procesos de mezcla o reacción, en los que la evolución de la viscosidad o el logro de una viscosidad objetivo definida resulta decisivo (como en procesos de homogeneización o detención de una reacción).

El viscosímetro de proceso modular puede utilizarse en prácticamente todos los sectores industriales, desde instalaciones estándar simples hasta situaciones de instalación altamente personalizadas. Aquellos usuarios que no dispongan de la posibilidad de conectar el transmisor a un sistema de control de procesos y utilicen el viscosímetro de proceso como sistema autónomo, pueden registrar los datos mediante el software ViscoView®. Nuestro catálogo contiene adaptadores de tubo, celdas de flujo, vainas térmicas y tubos de inmersión, así como convertidores de protocolo e interfaz.

Los sensores ViscoScope®, fabricados con acero inoxidable de primera calidad, destacan por su diseño inteligente y robusto. Todas las partes en contacto con el proceso están completamente soldadas, lo que elimina el riesgo de desgaste de componentes móviles o de fugas que puedan dañar el interior del alojamiento del sensor. Dado que la temperatura tiene una influencia significativa sobre la viscosidad, cada viscosímetro ViscoScope® incorpora una Pt100 integrada en el sensor.

En otras palabras:

La viscosidad y la temperatura se miden simultáneamente y en un momento dado. Estos dos parámetros son esenciales para la determinación de una viscosidad compensada por temperatura.

Otras características destacadas son la capacidad CIP/SIP, el acabado superficial con Ra < 0,8 µm, la instalación sin espacios muertos y la instalación en zonas con seguridad intrínseca.

El sensor VA-100 de fabricación en serie está disponible en un plazo breve con dos variantes de sensor dentro de una misma clase de temperatura y con tres tipos distintos de conexión al proceso. La fabricación personalizada del modelo ViscoScope® VA-300, realizada bajo pedido, permite una numerosas variantes y garantiza una integración óptima tanto en instalaciones nuevas como existentes.

Gracias a esta diversidad en diseño, es posible evitar en muchos casos la modificación de los puntos de instalación previstos o se pueden adaptar con esfuerzo mínimo.

Documentos y descargas

Hoja de datos

Datos generales

Instrucciones de instalación y funcionamiento

Certificado de prueba

Declaración de conformidad

Vídeo sobre el producto

Productos relacionados

ViscoScope® VA-300

Viscosímetro de proceso en línea libre de mantenimiento para la medición de viscosidad en tiempo real.

VS-D250

Transmisor para sensores de viscosidad ViscoScope

Fluidix Lub-VDT

Sensor de condición de aceite para la supervisión permanente de las propiedades mecánicas de líquidos.