Description

The tank level indicator is a mechanically actuated indication operating "on the spot”. It permits a high degree of safety and flexibility thanks to separate points of measurement and indication.

Technical Data

Properties

- Tank connection

- Flansch ab DN 80 (Sonderanschlüsse auf Wunsch)

- Material

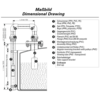

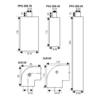

- siehe Maßbild

- Material Tube

- PVC, transparent | Ø 50 x 1,8 | Ø 63 x 3,0

- Operating temperature

- –20...+60 °C

- Operating pressure

- atmosphärisch

Material Float

- PPH

- Ø 70 mm 460 g

- PVC

- Ø 70 mm 455 g

- PPH

- Ø 40 mm 370g

- PE

- Ø 70 mm ca. 450 g

Material Rope

- PPH

- (rot, Ø 2 mm) ~ 2 g/m

- Polyester

- (bunt, Ø 2 mm) ~ 4 g/m

- PTFE

- (weiss, Ø 3 mm) ~ 10 g/m

MTA application-specific configuration

MTA - [ 1 ] - [ 2 ] - [ 3 ] - [ 4 ]

Further product information

Its simple operating principle is impressive, requiring no energy supply and ensuring a high operational safety. The tank level indicator can be operated in extremely varying conditions and is also suitable if there is not much space above the tank.

It may be used with tanks for water-endangering, non-flammable liquids for which no bottom or side panel fillers are permitted. Aggressive, highly viscous or polluted media can be monitored with the tank level indicator. In addition, the system can be adapted to liquids with different specific gravities. The tank level indicator consists of a float which is connected to the counterweight by a flexible rope. The counterweight is made of PVC and designed as a hollow body. It can be additionally loaded to permit adaptation to various media. Rope and float are guided in a PVC piping system which is hermetically sealed from the surroundings. To reduce friction, the rope is guided via pulleys in angular reversing brackets.

If desired, the viewing tube can be supplied with a discharge opening for condensate. The liquid level fluctuations are detected by the float and transferred to the counterweight via the traction rope. The counterweight with built-in permanent magnet is also used as an indicator panel. It displays the liquid level of the tank proportionally reversed outside the container. The permanent magnet in the counterweight actuates the infinitely variable switching contacts and/or controls the continuous level sensor TK-307.

Indication can also be achieved with magnetic flaps. The permanent magnet rotates small aluminum wafers with inserted bar magnets. When the level rises these are turned from white to red, and when the level falls from red to white.