In-line flow measurement system in open or closed pipes and channels

-

Fluid.iO Sensor + Control GmbH & Co. KG

Fluid.iO Sensor + Control GmbH & Co. KG

- Jun 1, 2022

- 6

- 5.5 minutes

Reliable flow measuring system for flow velocity and fill level. The flow measuring system enables flow measurement in turbid and aggressive liquids and is suitable for applications in Ex and non-Ex areas.

In-line flow measurement system in open or closed pipes and channels

Ultrasonic flow sensor for (waste) water and industrial waters

The flow measurement system enables flow measurement in cloudy and aggressive liquids and is suitable for applications in Ex and non-Ex areas. The ATEX certified measuring system consists of the DSM-2420 flow meter and the FDL400 data logger or Ex power supply unit SG2420.

The sensor is installed in partially or completely filled pipes and channels and delivers reliable measurement results from fill levels of just 3cm. The flow velocity is recorded using an ultrasonic measuring principle (Doppler effect), and the fill level is determined hydrostatically.

The measurement signals are evaluated using the compatible data logger or can be integrated into other existing measurement, alarm and control systems. The data logger (FDL400) saves the measured values on an SD card and also enables the flow rate to be calculated and limit values to be monitored.

The robust measuring system is suitable for flow measurement for all types of turbid, aggressive and non-aggressive liquids in the water and wastewater industry, as well as in industrial wastewater networks (beverage production, process water). The measurement is carried out in-line and flexibly in standardized and individual pipe and channel geometries.

Continuous in-line flow measurement: Your advantages as a system operator

-

Optimization in the planning or operation of your sewer network

-

Support for efficient system operation

-

Sensor-based control of systems and processes in water management

-

Increased environmental protection

-

Ideal for self-monitoring of wastewater systems

-

Easy installation in existing sewer structures without any on-site measures

ATEX certified

Developed for use in adverse environments: Reliable measurement in potentially explosive atmospheres and in aggressive media.

Data logger FDL400

- ATEX certified data logger with integrated Ex barrier

- functions as sensor supply and evaluation device for DSM2420

- Compact dimensions

- mounting on DIN rail or wall

- Calculation and display of flow velocity, fill level, flow and quantity

- 4-line, illuminated LCD

- control buttons for device configuration

- SD card: saving the measured values; loading and transferring device settings

- 4 digital signal outputs

- 3 analog 4…20mA signal outputs

- Measured value output freely configurable

- 1 fixed alarm output

- Input and monitoring of limit values

Flow sensor DSM2420

- Housing made of special plastic; resistant to aggressive media found in (waste) water

- ATEX-certified with EC type examination certificate

- Reliable and precise in-line measurement of flow velocity (ultrasonic) and filling level (hydrostatic)

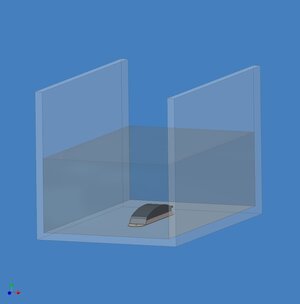

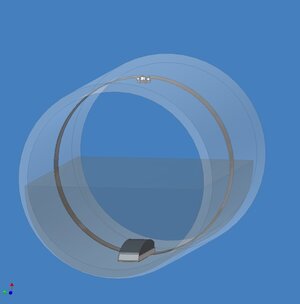

- Installation via mounting shoe on the channel floor or individually via a tensioned channel ring

- 4…20mA signal output for flow velocity and filling level

- 15m standard length for cable with integrated pressure compensation line; longer lengths possible

- Evaluation of the measurement signals via a suitable evaluation device

DSM2420

Sensor for simultaneous measuring flow velocity and filling level

The DSM2420 sensor is a combined sensor for simultaneous measuring flow velocity and level in open or accessible closed channels of all types and shapes.

FDL400

Flow Data Logger

The FDL400 "Flow Data Logger 400" measuring device is suitable for measuring the flow of water and wastewater in fully or partially filled sewers or pipes of various geometries.

Our application engineers advise you personally, comprehensively and professionally!

Simply contact us by phone or e-mail!